How About the High-Temperature Resistance of PET Protective Film?

What is PET Protective Film?

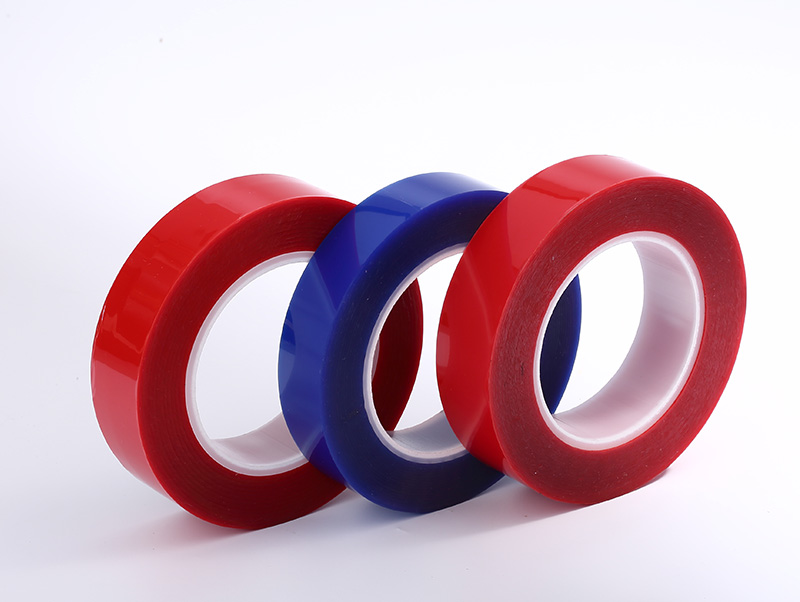

PET (Polyethylene Terephthalate) protective film is widely used for its durability and transparency. It provides excellent surface protection against scratches, dust, and contaminants. However, one of its key advantages is its high-temperature resistance.

How Much Heat Can PET Protective Film Withstand?

PET protective film can endure temperatures between 120°C and 150°C without losing its structural integrity. Some high-performance variants can withstand up to 200°C for short durations.

Factors Affecting PET Film’s Heat Resistance

1. Thickness of the Film

Thicker PET films generally offer better resistance to heat. The additional material helps in reducing heat penetration and deformation.

2. Coatings and Additives

Special coatings improve heat resistance. Silicone-based or heat-resistant polymer coatings enhance the film’s ability to withstand extreme conditions.

3. Duration of Heat Exposure

Short bursts of high temperatures are less damaging compared to prolonged exposure. PET films can handle brief spikes in temperature better than continuous heat.

Applications of High-Temperature PET Protective Films

1. Electronics Industry

PET films protect electronic screens, circuit boards, and components that are exposed to moderate heat levels during manufacturing.

2. Automotive Sector

Used for dashboard protection, Pet High Temperature Protective Films resist heat from sunlight and engine heat, preventing surface damage.

3. Industrial Manufacturing

PET protective films are applied in processes that require thermal resistance, such as lamination, printing, and coating applications.

Advantages of PET Protective Film in High-Temperature Environments

Stable Performance: Maintains clarity and strength under heat stress.

Scratch and Abrasion Resistance: Protects surfaces while enduring high temperatures.

Chemical Resistance: Withstands exposure to solvents and cleaning agents.

Conclusion

PET protective film provides excellent high-temperature resistance, making it ideal for multiple industries. Its ability to endure heat, combined with durability and transparency, ensures reliable performance in demanding applications.