What factors should be considered when choosing a powder filling machine?

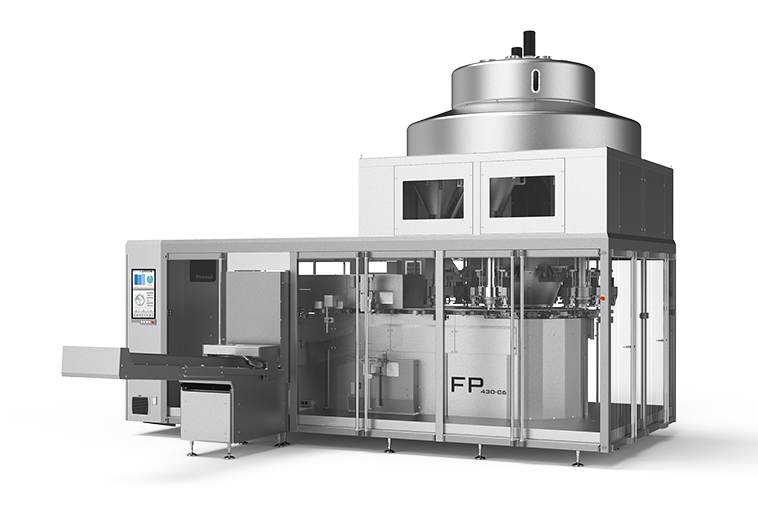

Powder filling machines are an important part of a complete powder production line. When choosing a packaging machine for your flowing powder products, there are a variety of models and brands to choose from. You need to determine which factors are most important to your business. Some of the most important factors include product characteristics, package type, automation level, filling accuracy, production capacity, and support services.

Product characteristics

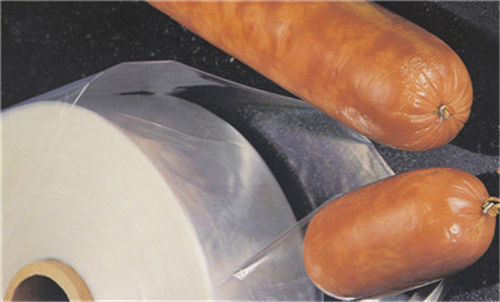

Powder filling machines can handle different types of powders or granules. Some are better suited for free-flowing powders, while others are best suited to handle non-free flowing products. In addition to the flow pattern of the powdered product, you should also consider its compressibility, viscosity, shape and size.

Packaging type

Choose how you will package your powder products. You can use sticks, bags, cans, bottles or any other type of container. For each type of packaging, you will need a different machine. In addition, the size of the container will determine how much your machine can fill. So, choose a powder filling machine that can handle different filling volumes.

Level of automation

One of the most important factors when choosing a powder filling machine is how much automation you need to produce. Some auger fillers are designed with advanced automation in mind, while others have features that allow for more manual operation. If your current output is relatively low and staffing is not a pressing concern, investing in a highly automated solution may not pay off reasonably well, but if you are looking for higher output, automation will greatly impact your performance.

Recommended article:What Size Tarp for Camping?

Glass Bottles for Pharmaceutical Use: Ensuring Safety and Quality

Which industries benefit the most from using shrink film for packaging and product protection?

What factors should businesses consider when choosing the right IML packaging solution for their specific products?

How do I compare the durability and thickness of different glass bottles for safe storage and transportation?

How does the design and material of snack pouches ensure the freshness and shelf life of the snacks?

Why is Eco Solvent Ink Gaining Popularity as a Sustainable Alternative in the Printing Industry?

Filling accuracy

The higher the value of the powdered product, the more important filling accuracy becomes. Filling accuracy in powder packaging can be tricky, as even environmental factors can affect the density of the product being fed into the filling assembly.

Production capacity

of powder filling machines have different characteristics and benefits. They are suitable for different production requirements. For example, if you want to package 1kg, 10kg, 20kg or 50kg of powder products, there are different powder filling machines to suit. This is because no single machine can meet all these needs. Therefore, it is vital to understand your production capacity.

Technical support and long-term customer experience

When you invest in capital equipment that you plan to have for decades, it is important to fully understand what your experience will be like if problems occur. If you're investing a lot of money in quality, reliable packaging machinery, you need to make sure that the quality of technical support, training and wear parts matches it.

Shanghai Dahe Packaging Machinery Co., Ltd. is one of the leading Powder & Granule packaging machinery manufacturer and complete tailor-made packing line solution provider in china. If you have any questions, please contact us for professional guidance.

What Is Tacky Sublimation Paper And Why Do You Need It?

Non Wet Strength Metallized Paper: Unveiling the Future of Packaging

How to Maintain a Barcode Printer: A Comprehensive Guide

The Advantages of LPG Cylinders: Clean, Efficient, and Versatile Energy Source

How to Make Perfect Popcorn in a Microwave Paper Bag?

Embracing Sustainability: The Advantages of Compostable Packaging Pouches

Exploring the Compatibility of Dye Ink in Printers